Miller Trailblazer 325 Owners Manual⁚ A Comprehensive Guide

This comprehensive guide provides essential information for operating and maintaining your Miller Trailblazer 325 welder/generator․ Access online versions or download PDF manuals for detailed instructions, parts lists, troubleshooting, and safety precautions․ Learn about advanced features like Wave Filter and Smart-Cor technology․ Find contact information for Miller Welds support․

Accessing the Manual

Obtaining your Miller Trailblazer 325 owner’s manual is straightforward․ Multiple avenues are available to ensure you have the necessary documentation for your machine․ First, check for a physical copy included with your welder/generator upon purchase․ This paper manual may contain quick-start guides and safety information․ Secondly, explore online resources․ MillerWelds․com is the official website, and there you’ll likely find downloadable PDF versions of the complete manual, often available in multiple languages for international users․ These online manuals are regularly updated to reflect any changes or improvements to the machine, ensuring you have the most current information․ Thirdly, consider contacting Miller directly․ Their customer service department can provide guidance on accessing the manual, answer any questions you may have, and offer assistance if you encounter difficulties finding the appropriate documentation․ Remember to always refer to the most recent version of the manual to ensure you are operating your Trailblazer 325 safely and efficiently․

Online Versions and PDF Downloads

Accessing your Miller Trailblazer 325 owner’s manual digitally offers significant advantages․ The official MillerWelds․com website is the primary source for online versions and downloadable PDF files․ These digital manuals often provide a more convenient and easily searchable alternative to a bulky printed version․ The PDF format allows for easy printing of specific sections if needed, saving paper and resources․ Online versions often incorporate hyperlinks, making navigation to different sections intuitive․ Furthermore, updates and revisions to the manual are readily available online, ensuring you always have access to the most current information, including safety updates and troubleshooting guides․ Searching for “Miller Trailblazer 325 manual PDF” on major search engines can also yield results, but always prioritize downloading from the official Miller website to ensure authenticity and accuracy․ This method guarantees you’re not working with outdated or potentially misleading information․ Remember to check the file size before downloading to ensure compatibility with your device and available storage space․

Manual Sections⁚ A Quick Overview

The Miller Trailblazer 325 owner’s manual is structured to provide a comprehensive guide for users of all experience levels․ Key sections typically include a detailed safety overview emphasizing crucial precautions before operation․ A thorough explanation of the machine’s controls and their functions is also provided, aiding in understanding the operational aspects․ A detailed parts list with diagrams is usually included, simplifying identification and ordering of replacement parts․ The manual will explain the proper procedures for routine maintenance, such as oil changes and filter replacements, ensuring optimal performance and longevity․ Troubleshooting sections often cover common issues and offer step-by-step solutions to help resolve problems efficiently․ Information on generator power output and runtime, welding capabilities, and arc performance are also crucial sections, providing insights into the machine’s capabilities and limitations․ Finally, sections dedicated to advanced technologies, such as Wave Filter and Smart-Cor, will provide explanations of their functions and benefits․ This structured approach ensures that users can quickly find the specific information they require․

Section 9⁚ Parts List and Recommended Spares

Section 9 of the Miller Trailblazer 325 owner’s manual is dedicated to providing a comprehensive parts list and recommendations for spare components․ This section is crucial for maintaining the welder’s optimal performance and extending its lifespan․ The parts list is typically detailed, including diagrams and part numbers for easy identification and ordering․ It covers a wide range of components, from essential engine parts like air filters and oil filters to crucial welding system components․ For engine maintenance, the list may include specific Kohler engine parts, given the frequent use of Kohler engines in this model․ The manual also suggests keeping a stock of readily consumable items, such as fuses (like the 30 Amp ATO type mentioned in some online resources)․ Beyond basic maintenance parts, the recommended spares section might include items prone to wear and tear during operation․ The inclusion of tune-up kits, potentially including specific components for Kohler Ch730 engines, illustrates the manual’s commitment to providing users with all necessary information for comprehensive maintenance․ This detailed approach allows users to proactively address potential issues and minimize downtime․

Engine Specifications and Maintenance

The Miller Trailblazer 325 owner’s manual dedicates a significant portion to detailing engine specifications and crucial maintenance procedures․ Understanding these aspects is vital for ensuring optimal performance and longevity․ This section typically outlines the engine’s type, model (often a Kohler engine, like the Ch730, based on online references), displacement, horsepower, and fuel type․ Detailed specifications concerning oil type, capacity, and recommended change intervals are usually provided․ The manual will guide users through essential maintenance tasks such as oil changes, air filter replacements, and fuel filter servicing, with step-by-step instructions and visual aids․ It emphasizes the importance of regular maintenance to prevent potential engine problems and maintain peak efficiency․ Specific recommendations regarding spark plugs, including their type and replacement schedule, are also likely included․ The section might also address troubleshooting common engine issues, offering guidance on diagnosing problems and potential solutions․ Furthermore, the manual may contain warnings about improper maintenance practices and their potential consequences․ Adherence to these guidelines ensures the engine’s reliable operation and contributes to the overall lifespan of the Trailblazer 325 welder/generator․

Troubleshooting and Error Codes

A dedicated section within the Miller Trailblazer 325 owner’s manual addresses troubleshooting and error codes․ This crucial part equips users with the knowledge to diagnose and resolve common issues independently․ The manual typically provides a comprehensive list of potential error codes, each accompanied by a detailed description of the problem it indicates․ For instance, codes might signal problems related to the engine, generator, welding system, or other components․ Along with the codes, the manual offers step-by-step troubleshooting guides to help determine the root cause of the problem․ These guides often involve checking fuses, inspecting connections, verifying fuel levels, or performing basic diagnostic tests․ In some cases, the manual may provide visual aids or diagrams to simplify the troubleshooting process․ The level of detail in the troubleshooting section varies, but it aims to empower users to address minor issues without needing external assistance․ However, it also emphasizes situations where professional intervention is necessary, directing users to contact Miller Welds or a qualified service technician for complex repairs or when troubleshooting steps fail to resolve the issue․ This section is crucial for maintaining the welder’s functionality and preventing further damage․

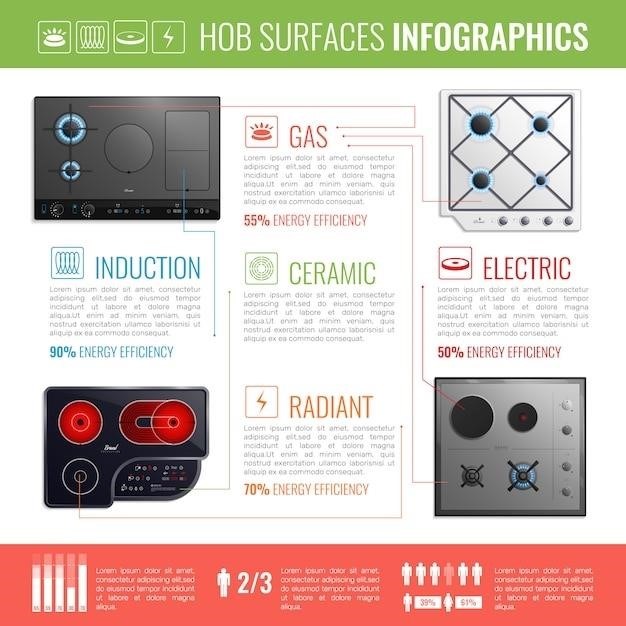

Generator Power Output and Runtime

The Miller Trailblazer 325 owner’s manual details the generator’s power output and runtime capabilities, crucial information for users needing auxiliary power․ Specifications for power output (measured in watts) are clearly stated, differentiating between continuous and peak power․ Understanding this distinction is key; continuous power represents the sustained output the generator can safely provide for extended periods, while peak power indicates the maximum output for short bursts․ The manual likely clarifies the impact of different loads on runtime․ For example, operating power-hungry tools will significantly reduce the generator’s runtime compared to lighter loads․ Factors influencing runtime are also explained, including fuel type, engine condition, and ambient temperature․ The manual may provide runtime charts or graphs illustrating the relationship between power consumption and operational duration under various conditions․ Information on fuel efficiency might also be included, allowing users to estimate fuel consumption based on expected power usage and runtime․ This section helps users plan effectively, ensuring sufficient power and runtime for their specific applications․ Understanding these parameters is essential for efficient and safe operation of the Miller Trailblazer 325’s generator capabilities․

Welding Capabilities and Arc Performance

The Miller Trailblazer 325 owner’s manual extensively covers its welding capabilities and arc performance, crucial aspects for welders․ The manual specifies the machine’s amperage range, detailing the minimum and maximum output currents achievable for various welding processes (e․g․, stick, TIG, MIG)․ It likely includes information on duty cycles, indicating the percentage of time the welder can operate at a specific current before overheating․ Understanding duty cycles is vital for preventing damage and ensuring consistent performance․ Arc performance characteristics are also described; this section may cover arc stability, ease of striking an arc, and penetration capabilities․ The manual might discuss the machine’s features designed to enhance arc performance, such as advanced arc control technologies or variable voltage settings․ Descriptions of how to adjust settings for optimal arc performance with different materials and thicknesses are usually provided․ The impact of different electrode types and sizes on arc stability and penetration is often discussed, giving users guidance on selecting the appropriate consumables․ Illustrations or diagrams may accompany the text to clarify the relationships between settings, electrode types, and resulting weld quality․ This section empowers users to achieve high-quality welds by understanding the machine’s capabilities and optimizing its settings for various welding tasks․

Advanced Technologies⁚ Wave Filter and Smart-Cor

The Miller Trailblazer 325 owner’s manual highlights its innovative technologies, Wave Filter and Smart-Cor, designed to enhance performance and efficiency․ The Wave Filter technology is likely explained as a system that significantly reduces voltage fluctuations and harmonic distortion in the welding power output․ This results in a smoother, more stable arc, crucial for consistent weld quality and reduced spatter․ The manual probably details how the Wave Filter minimizes the impact of electrical noise and power surges, ensuring reliable welding even in challenging environments with fluctuating power supplies․ Smart-Cor technology, often described as a sophisticated engine control system, is likely explained as optimizing engine speed and fuel efficiency․ This section might detail how Smart-Cor dynamically adjusts engine speed to match welding demands, maximizing runtime on a single tank of fuel․ The manual would likely include diagrams or illustrations explaining the workings of both systems, showing how they contribute to improved arc characteristics, fuel efficiency, and overall welder performance․ By understanding these technologies, users can appreciate the advanced engineering incorporated into the Trailblazer 325 and leverage its features for optimal welding outcomes and operational efficiency․

Safety Precautions and Important Notices

The Miller Trailblazer 325 owner’s manual emphasizes safety as a paramount concern․ This section likely begins by strongly advising users to thoroughly read all safety instructions before operating the machine․ Detailed warnings about high-voltage electricity are probable, emphasizing the dangers of electric shock and the importance of using appropriate personal protective equipment (PPE), such as insulated gloves and eye protection․ The manual will likely detail safe handling procedures for the generator’s fuel, stressing the risks of fire and explosion associated with gasoline or diesel fumes․ Proper ventilation during operation and storage are likely emphasized․ Safe operating practices for welding itself are certainly included, warning about arc flash hazards, the potential for burns from hot metal, and the necessity of using appropriate shielding gases․ The importance of working in a well-ventilated area to avoid inhaling harmful fumes is also likely highlighted․ Furthermore, the manual will likely provide instructions on the proper shutdown procedures to prevent accidents․ Regular maintenance checks outlined in the manual, including engine oil and filter changes, are crucial for preventing malfunctions and ensuring safe operation․ Ignoring these safety precautions could lead to serious injury or equipment damage․

Finding Replacement Parts

Locating replacement parts for your Miller Trailblazer 325 is facilitated through several avenues, as detailed in the owner’s manual․ The manual likely provides a comprehensive parts list (Section 9, as referenced in online excerpts), including part numbers and descriptions, simplifying the ordering process․ Miller’s official website (MillerWelds․com, mentioned in the provided text) is a primary resource․ The site likely features an online parts catalog where users can search by part number or description to identify and order needed components․ Authorized Miller distributors are another key source; the manual likely includes a dealer locator tool or a list of authorized dealers in your region․ These distributors stock common parts and can order specialized components․ Online retailers specializing in welding equipment and parts also represent viable options, though users should exercise caution and ensure they are purchasing genuine Miller components to maintain performance and warranty validity․ When ordering, always reference the specific part number from the manual or the online parts catalog to ensure accuracy․ For less common or obsolete parts, contacting Miller customer support directly is recommended; they may have access to parts not readily available through other channels or can provide guidance on finding suitable substitutes․ Remember to keep your serial number handy when seeking replacement parts, as this information is crucial for accurate identification and ordering․

Additional Resources and Support

Beyond the owner’s manual, Miller offers a wealth of supplementary resources to enhance your Trailblazer 325 experience․ Their official website, MillerWelds․com, is a central hub for information, including FAQs, troubleshooting guides, and software updates (if applicable)․ The site often provides access to video tutorials demonstrating proper operation, maintenance procedures, and advanced techniques․ These videos offer visual aids supplementing the written instructions in the manual, aiding in comprehension and practical application․ Online forums and communities dedicated to Miller welding equipment provide a platform for users to share experiences, ask questions, and receive advice from fellow users and experienced welders․ This peer-to-peer support can be invaluable for troubleshooting minor issues or discovering unconventional uses for the machine․ Miller’s customer service department provides direct support via phone or email․ Their contact details are usually found on their website or within the manual itself․ They offer assistance with technical questions, parts ordering, and warranty claims․ Finally, consider consulting local welding supply stores or rental companies․ These businesses may offer additional training resources or be able to provide expert advice on specific welding applications or maintenance issues․ Proactive engagement with these additional resources ensures you gain a comprehensive understanding of your Miller Trailblazer 325 and maximize its capabilities․

Contacting Miller Welds for Assistance

Should you encounter any difficulties operating or maintaining your Miller Trailblazer 325, accessing Miller Welds’ support network is crucial․ Their website, MillerWelds․com, is the primary point of contact, offering comprehensive FAQs, troubleshooting guides, and downloadable resources․ The site likely provides contact information for their customer service department, including phone numbers and email addresses․ Before contacting them directly, carefully review the owner’s manual’s troubleshooting section․ This often addresses common issues and may resolve your problem without needing further assistance․ When contacting Miller Welds, be prepared to provide your machine’s serial number, a concise description of the problem, and any relevant error codes displayed on the unit․ This information streamlines the troubleshooting process․ For warranty-related issues, ensure you have your proof of purchase readily available․ Miller Welds may offer various support channels, such as live chat, phone support, or email․ Choose the method most convenient for your situation․ Expect a response within a reasonable timeframe․ If the issue requires on-site service, Miller Welds may direct you to authorized service centers in your area․ Their website might list these centers, providing contact details and service area information․ Remember, proactive communication is key to resolving any issues promptly and ensuring your Miller Trailblazer 325 remains a reliable and productive piece of equipment․